Basic Info.

Model NO.

MT-MN

Cutting Speed

Max.30m/Min

Location Precision

±1.015mm

Repeated Positioning Accuracy

0.15-0.3mm

Power Source

AC110/220V ± 10%/50/60Hz

Working Temperature

0-40ºC

Gross Power

<4kw

Controlling Formats Supported

DSP High Speed Controller

Operating Temperature

10ºC-40ºC

Safety Protection Class

IP54

Transport Package

Standard Export Wooden Box

Trademark

MACTRON

Origin

Guangdong, China

Production Capacity

50sets/Month

Product Description

Product Description

MT-MN series metal and nonmetal laser cutting machine is suitable for metal and non-metal sheet cutting, which is equipped with steel welded frame, stable, good rigidity, high dynamic response that ensures no deformation on long-term working condition.

Multifunctional laser cutting head suitable metal and nonmetal materials cutting. Fixed optical path compensation system ensures consistency of laser spot quality within the whole cutting area. Imported linear guide and screw transportation system with high rigidity, high transmission torque, and eliminating vibration, over fiber times higher in accuracy compared with the belt transmission system.

Self-developed new generation touch screen motion controller with touch-screen software design. The control system supports automatic focusing for metal cutting and nonmetal processing, which makes to cut various material thickness easily with good effect.

Applicable Material

Widely applied to large format material cutting, such as carbon steel, stainless steel, acrylics, MDF and etc.

Applicable Industry

Applicable Fields:advertisement making, thin metal processing, die-boards cutting etc.

Parameters

Machine Advantages

1) Can cut lines and holes with different diameters from different directions on the pipe, and meet centrifugal and non-centrifugal vertical intersection condition for branch and main pipe axis.

2) Can cut column Crossed Lines at the end of branch pipe, and meet centrifugal and non-centrifugal vertical intersection condition for branch and main pipe axis.

3) Can cut inclined section at the end section of the pipe.

4) Can cut branch pipe intersected with the main circular pipe.

5) Can cut variable angle bevel surface

6) Can cut square hole, waist-shaped holes and circular hole on the pipe.

7) Can truncate the pipe.

8) Can cut all kinds of graphics on the surface of the square pipe.

Product Sample Display

Other Product Recommendation

Production Process

Packaging & Shipping

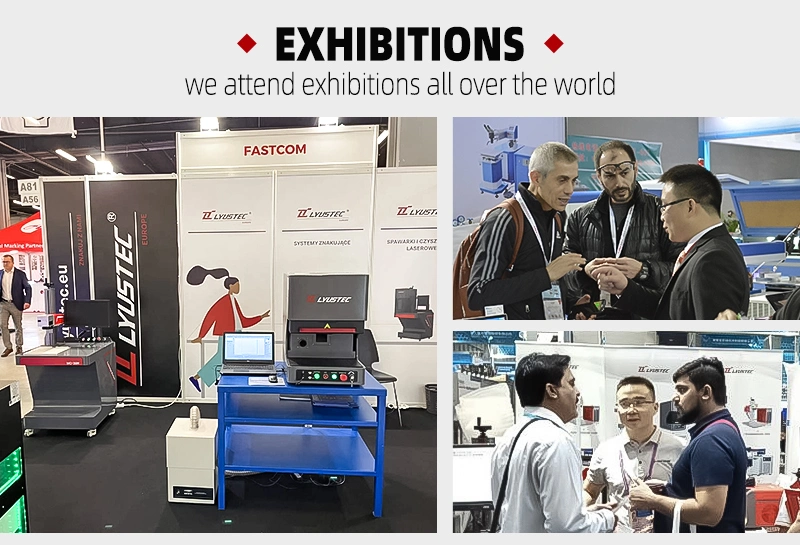

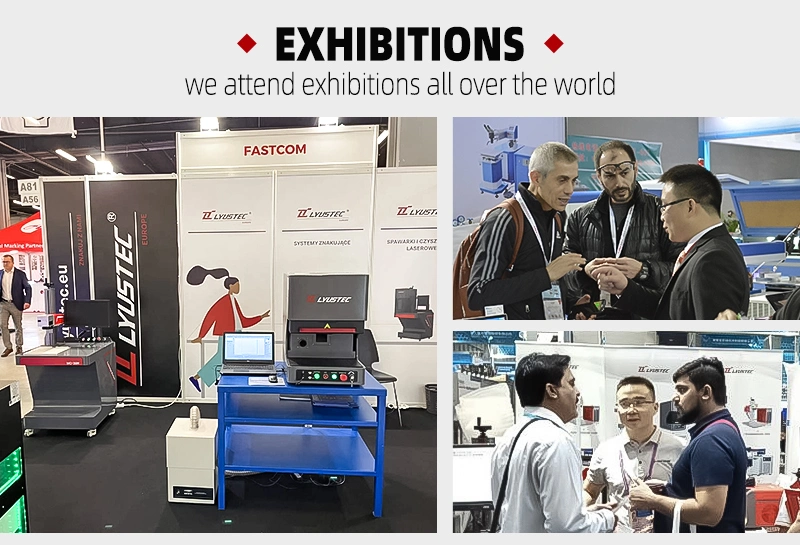

Company Information

Dongguan Mactron Technology CO.,Ltd is a new & hi-tech enterprise ,located in international famous manufacturing city--Dongguan,integrated the laser,precision machinery,CNC and modern management,specializing in developing ,manufacturing and selling of industrial laser equipment and customized automation device.

Mactron's mainly product is including:

Laser Cutting Machine, Laser Engraving Machine, Laser Marking Machine, Mini Laser Engraver, CNC Laser Cutter, YAG Laser System, Diode Pump Laser Equipment, Co2 Laser Tube, Laser Focusing Lens, Laser Reflector Mirror, Laser Power Supply, Laser Cooler Unit, Laser Scanner Head, Laser Control System, Laser Cutting Head, Beam Expander, Red Pointer, Krypton Lamp and accessories etc.

Mactron Technology's business tenet is "Do Honest Bussiness ".

Mactron Technology's managerial spirit: "Solidarity, Exertion, Truthfulness, Innovation"

Certifications

FAQ

1)What are the primary products of your company?

Our primary products include laser marking machine, laser engraving machine, laser cutting machine, laser welding machine, and laser spare parts.

2) Where is your fiber laser equipment applied to?

Our Fiber Laser Marking Machine is suitable for all kind of metal, industrial plastic, electroplates, metal-coated materials, rubbers, ceramics and so on.

3) What are the advantages of your laser equipment?

Our laser equipment has several advantages.

High quality and precision are the featured properties of our laser marking machine. Our laser marking machine employs the domestic leading "Smart Engraving" technology, which could clearly engrave 2mm characters and 1mm letters on the materials.

4) How to do control the quality when you produce laser equipment?

We introduce international advanced production technology, and strictly implement a series of measures of quality and cost control to ensure the quality of laser marking machine. In addition, all raw materials are strictly inspected in accordance with international standards before they are put into production.

MT-MN series metal and nonmetal laser cutting machine is suitable for metal and non-metal sheet cutting, which is equipped with steel welded frame, stable, good rigidity, high dynamic response that ensures no deformation on long-term working condition.

Multifunctional laser cutting head suitable metal and nonmetal materials cutting. Fixed optical path compensation system ensures consistency of laser spot quality within the whole cutting area. Imported linear guide and screw transportation system with high rigidity, high transmission torque, and eliminating vibration, over fiber times higher in accuracy compared with the belt transmission system.

Self-developed new generation touch screen motion controller with touch-screen software design. The control system supports automatic focusing for metal cutting and nonmetal processing, which makes to cut various material thickness easily with good effect.

Applicable Material

Widely applied to large format material cutting, such as carbon steel, stainless steel, acrylics, MDF and etc.

Applicable Industry

Applicable Fields:advertisement making, thin metal processing, die-boards cutting etc.

Parameters

| Laser Type | CO2 Glass Laser Tube/(RF Metal CO2 Laser Tube Optional) |

| Peak Laser Power | 150W/200W/300W/400W/600W (Optional ) |

| Wavelength | 10.6um |

| Cutting Speed | Max.30M/Min |

| Focal Length | 50.8,63.5,76.2,127mm |

| Cooling Mode | Water Cooling and Protection System |

| Location Precision | 0.05mm |

| Controlling Formats Supported | DSP High Speed Controller |

| Graphic Formats Supported | PLT,DST,AI,DXF,BMP,JPG,CAD,CDR,DWG |

| Operating temperature | 10ºC-40ºC |

| Warranty | 1 Year |

| Beam Quality | <1.2M2 |

| Humidity | 5% to 85% (No Condensed ) |

| Gross Power | <4000W |

| Min.Line Width | 0.15-0.3mm |

| Power source | AC110V/220V± 10%, 50/60HZ |

| Processing Area | 1300*900mm(Optional) |

| Working Environment | Clean, Free of Dust |

| Safety Protection Class | Ip54 |

| Laser Generator Safety Class | IV |

Machine Advantages

1) Can cut lines and holes with different diameters from different directions on the pipe, and meet centrifugal and non-centrifugal vertical intersection condition for branch and main pipe axis.

2) Can cut column Crossed Lines at the end of branch pipe, and meet centrifugal and non-centrifugal vertical intersection condition for branch and main pipe axis.

3) Can cut inclined section at the end section of the pipe.

4) Can cut branch pipe intersected with the main circular pipe.

5) Can cut variable angle bevel surface

6) Can cut square hole, waist-shaped holes and circular hole on the pipe.

7) Can truncate the pipe.

8) Can cut all kinds of graphics on the surface of the square pipe.

Product Sample Display

Other Product Recommendation

Production Process

Packaging & Shipping

Company Information

Dongguan Mactron Technology CO.,Ltd is a new & hi-tech enterprise ,located in international famous manufacturing city--Dongguan,integrated the laser,precision machinery,CNC and modern management,specializing in developing ,manufacturing and selling of industrial laser equipment and customized automation device.

Mactron's mainly product is including:

Laser Cutting Machine, Laser Engraving Machine, Laser Marking Machine, Mini Laser Engraver, CNC Laser Cutter, YAG Laser System, Diode Pump Laser Equipment, Co2 Laser Tube, Laser Focusing Lens, Laser Reflector Mirror, Laser Power Supply, Laser Cooler Unit, Laser Scanner Head, Laser Control System, Laser Cutting Head, Beam Expander, Red Pointer, Krypton Lamp and accessories etc.

Mactron Technology's business tenet is "Do Honest Bussiness ".

Mactron Technology's managerial spirit: "Solidarity, Exertion, Truthfulness, Innovation"

Certifications

FAQ

1)What are the primary products of your company?

Our primary products include laser marking machine, laser engraving machine, laser cutting machine, laser welding machine, and laser spare parts.

2) Where is your fiber laser equipment applied to?

Our Fiber Laser Marking Machine is suitable for all kind of metal, industrial plastic, electroplates, metal-coated materials, rubbers, ceramics and so on.

3) What are the advantages of your laser equipment?

Our laser equipment has several advantages.

High quality and precision are the featured properties of our laser marking machine. Our laser marking machine employs the domestic leading "Smart Engraving" technology, which could clearly engrave 2mm characters and 1mm letters on the materials.

4) How to do control the quality when you produce laser equipment?

We introduce international advanced production technology, and strictly implement a series of measures of quality and cost control to ensure the quality of laser marking machine. In addition, all raw materials are strictly inspected in accordance with international standards before they are put into production.